Clarifier Waste Water Treatment Rectangular Sedimentation Tank Bridge Type Mud Sludge Scraper

Product DescriptionDrive Mud Scraper Sludge Thickerner for Sedimentation Tank in Sewage Treatment ProjectProduct DescriptionApplicationUrban sewage treatment plantsWater worksChemical plantsFood proce···

Introduction

Product Description

Clarifier Waste Water Treatment Rectangular Sedimentation Tank Bridge Type Mud Sludge Scraper

Product Description

Application

Urban sewage treatment plants

Water works

Chemical plants

Food processing plants

Other industrial wastewater treatment projec

Description

QD sludge scraper has Full bridge, Half bridge and Truss type.

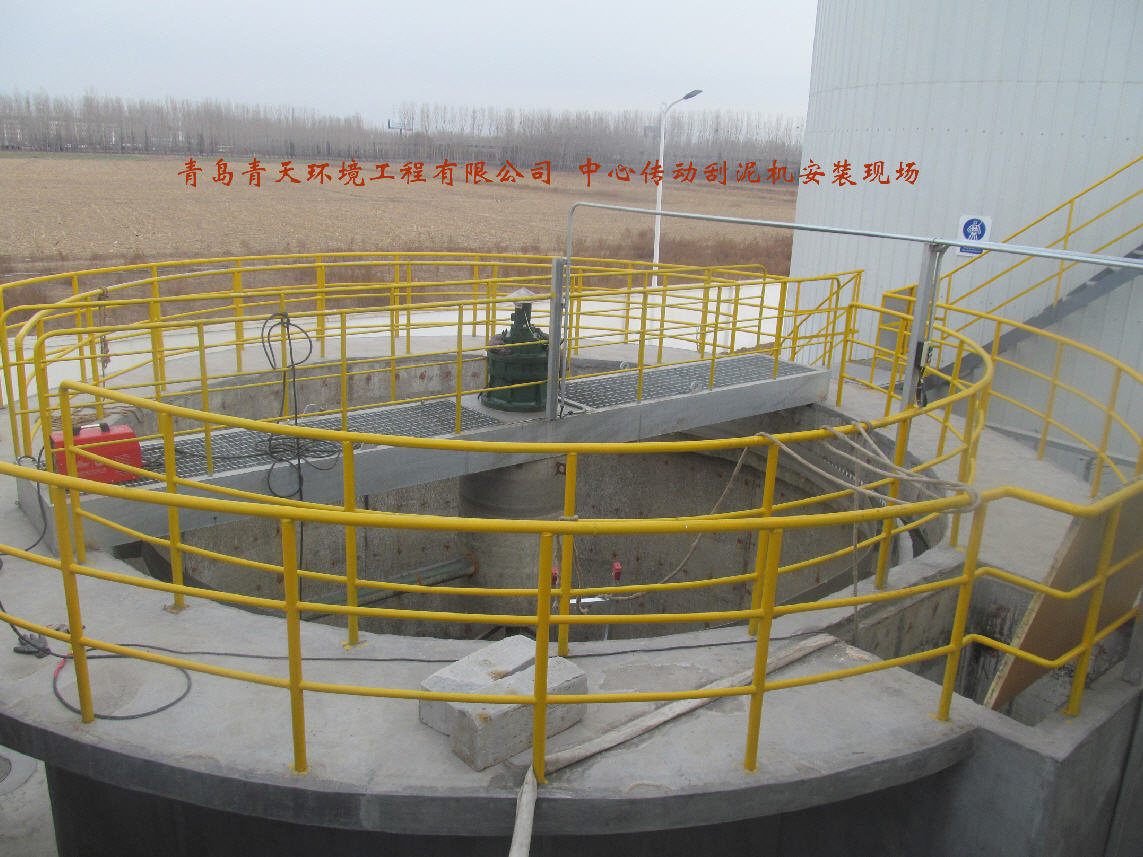

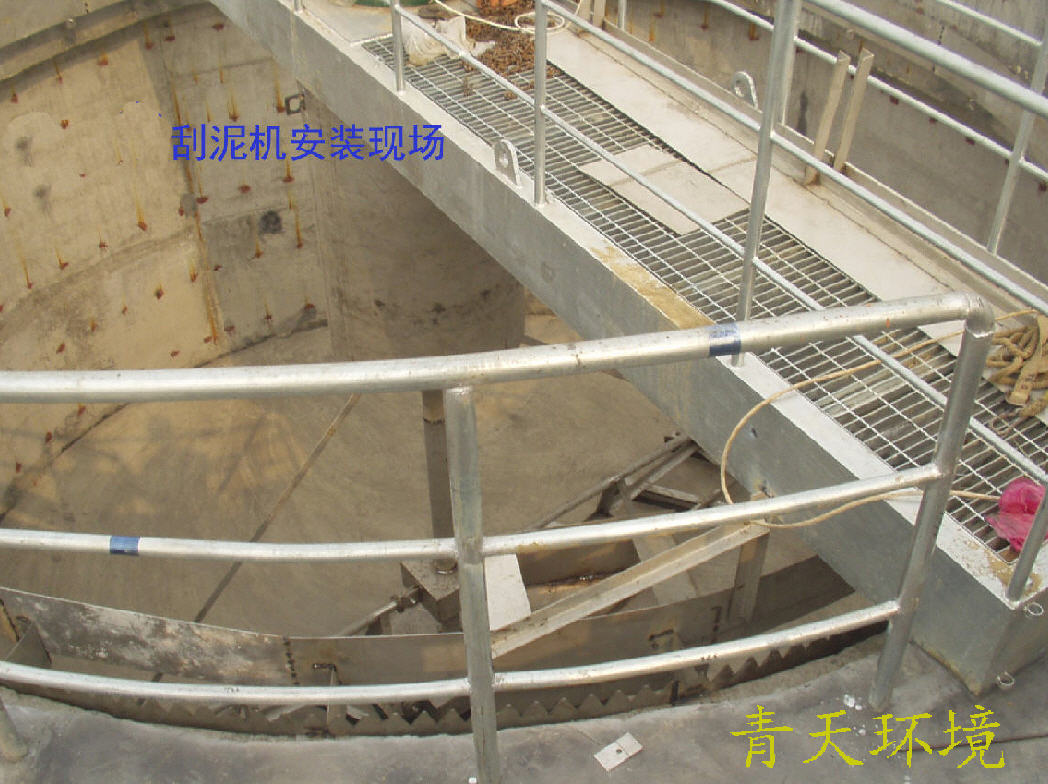

Full/half bridge sludge scraper is suitable for the collection and discharge of sludge in circular radial sedimentation tank. It is mainly composed of working bridge, center rotating support, scraper scraper, diversion cylinder, driving mechanism, slag retaining and slag discharging device, etc., which can meet the requirements of DN5-DN50 kinds of specifications and different water quantity of sedimentation tank.

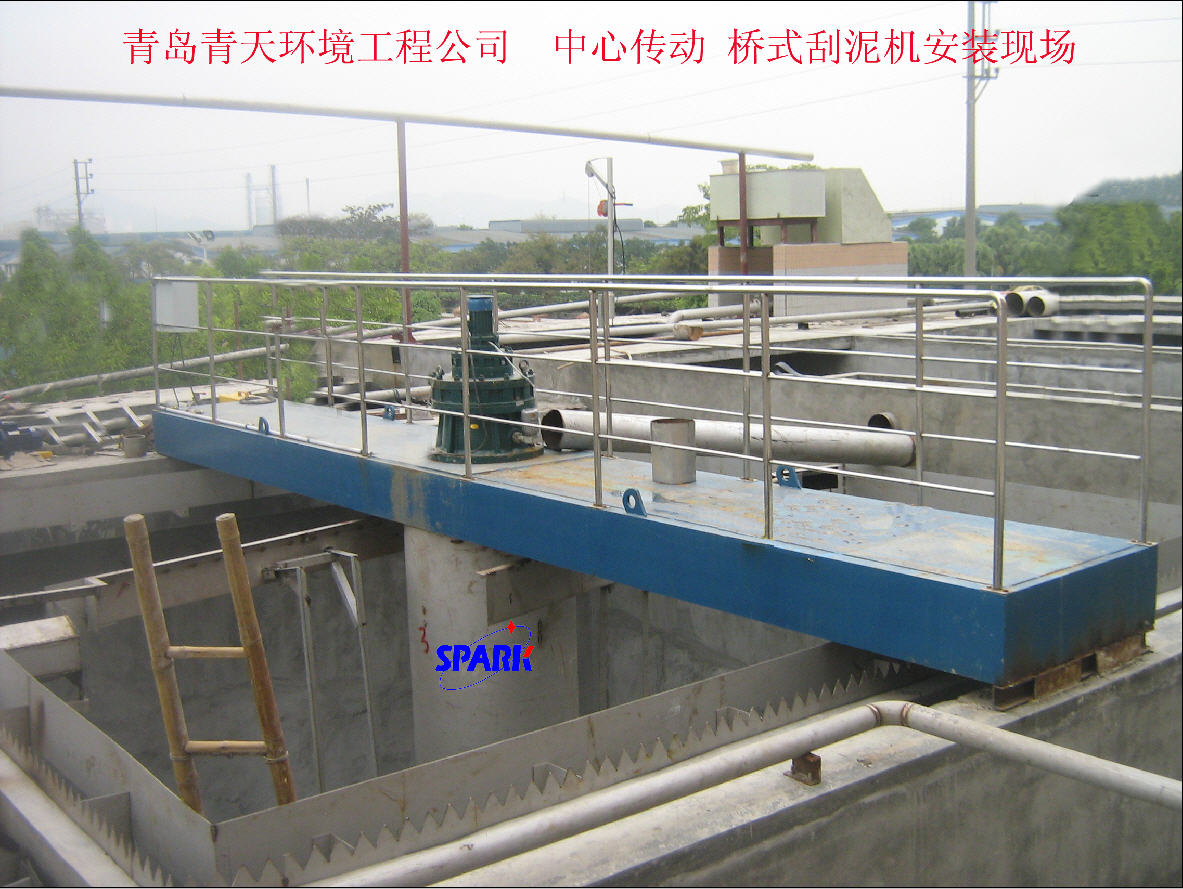

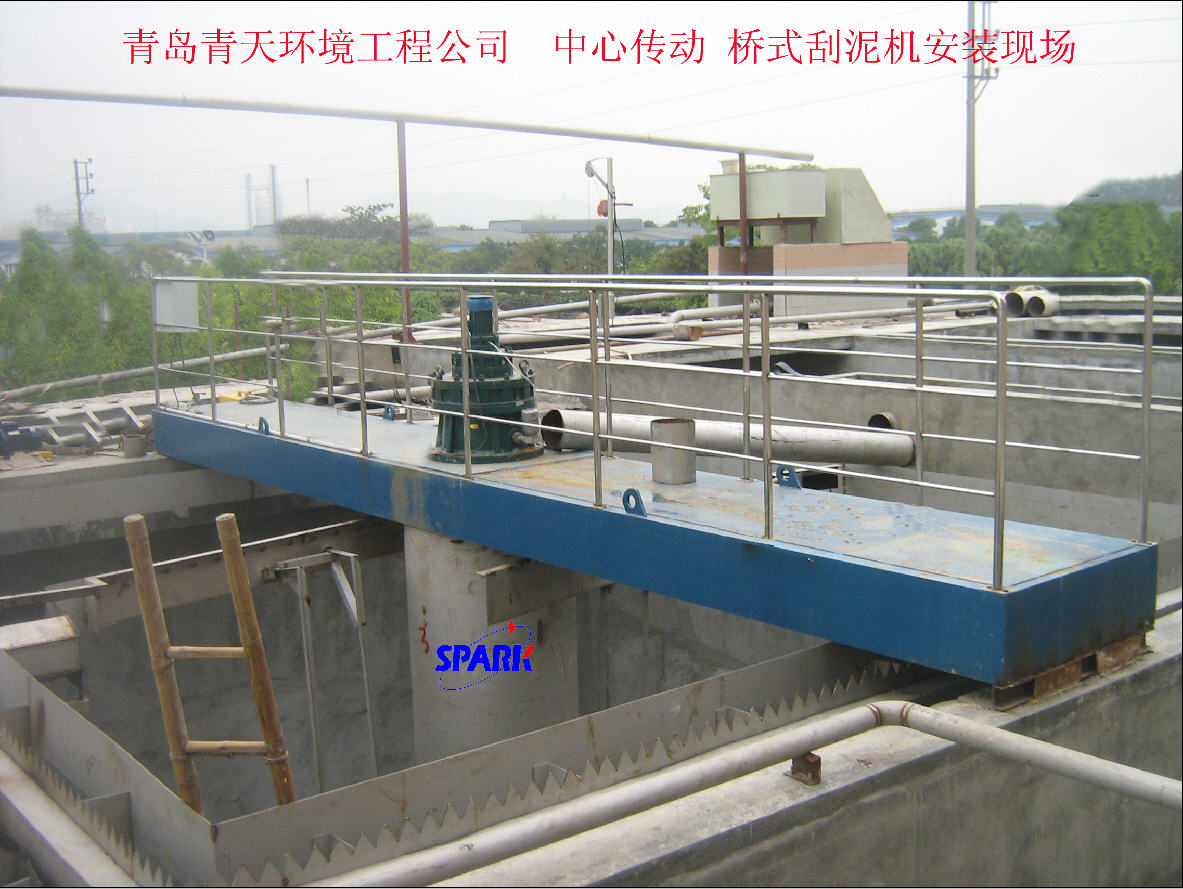

The driving-type sludge scraper is suitable for collecting and discharging sludge from rectangular flat-flow sedimentation tank. It is mainly composed of working bridge, transmission device, scraper, sludge lifting pump and so on.

Working principle

Sludge scraper, sewage by central piers by diverting tube diffusion, mixture of massive particles by precipitation in the bottom sludge layer, the proportion of light floating in the liquid level, driving gear drives the work mud scraper bridge and set the sludge from pool week step by step toward the center of silt orifice discharge pool, sludge scraper along the guide tube will be floating scum on the liquid surface into the pool within weeks of discharge hopper, discharge outside the pool.

Features

1. Working bridge can be used half or full bridge, its material can be carbon steel, stainless steel, etc.

2. The scraper adopts rubber combination structure, scraping mud thoroughly. The scraper collects mud with spiral trajectory, which has good continuity and high efficiency of mud collection.

3. System control cabinet adopts outdoor type, safe and reliable, can be controlled randomly.

4. Smooth operation, safe and reliable work.

5. Simple structure, energy saving, convenient maintenance and management.

6. The size, material and other configuration of the equipment can be determined according to user requirements.

Product Parameters

QD Full Bridge Type Scraper Parameter

| Model | Dia. Of Pond (m) | Depth. Of Pond (m) | Speed of mud scraper (m/min) | Power(kw/min) |

| QD-3 | 3.0 | 3.0 | 1-2 | 0.37 |

| QD-4 | 4.0 | 3.5 | 1-2 | 0.75 |

| QD-5 | 5.0 | 4.0 | 1-2 | 0.75 |

| QD-6 | 6.0 | 4.0 | 1-2 | 0.75 |

| QD-8 | 8.0 | 4.5 | 1-2 | 1.50 |

| QD-10 | 10.0 | 4.5 | 1-2 | 1.50 |

| QD-12 | 12.0 | 5.0 | 1-2 | 1.50 |

| QD-14 | 14.0 | 5.0 | 2-3 | 1.50 |

| QD-16 | 16.0 | 5.0 | 2-3 | 1.50 |

QD Half Bridge Type Scraper Parameter

| Model | Dia. Of Pond (m) | Depth. Of Pond (m) | Speed of mud scraper (m/min) | Power(kw/min) |

| QD-8 | 8.0 | 3.0 | 1-2 | 0.55 |

| QD-10 | 10.0 | 3.0 | 1-2 | 0.75 |

| QD-12 | 12.0 | 3.5 | 1-2 | 0.75 |

| QD-14 | 14.0 | 3.5 | 1-2 | 1.10 |

| QD-16 | 16.0 | 3.5 | 1-2 | 1.10 |

| QD-18 | 18.0 | 3.5 | 1-2 | 1.50 |

| QD-20 | 20.0 | 3.5 | 1-2 | 1.50 |

| QD-25 | 25.0 | 3.5 | 1-2 | 2.20 |

| QD-30 | 30.0 | 4.0 | 1-3 | 2.20 |

| QD-35 | 35.0 | 4.0 | 1-3 | 3.00 |

CertificationsCompany Profile

QingdaoBluesky Environmental Engineering Co., Ltd. is established in 1997,it is one of scientific research design, equipment manufacture, installation, commissioning and training services as one integrated technology-oriented enterprises in water treatment industry. It is holding by Qingdao Spark Textile Machine Co., Ltd which is a national Spark Industrial Group, national second-level and large-scale comprehensive enterprise group in China.

Our Advantages

We use the advanced technology and equipment over the world. Our main productions: Integrated Sewage Treatment Equipment, MBR Sewage Treatment Equipment(MBR), ElectrocoagulationSewage Treatment Plant(EC Plant), Reverse Osmosis Filteration Equipment(RO System), Dissolved Air Flotation Machine(DAF), Cavitation air Flotation Machine(CAF), Aerator, Screw Press Sludge Dewatering Machine, Automatic Chemical Dissolved and Dosing machine, Sludge Scraper, Slag Scraper, The micro bubble generator, USAB anaerobic reactor, Bar Screen, Sand Filter and so on series products.We have professional engineer support, high efficiency sales team and competitive price superiority, and attract customers from all over the world, we export to over 40 countries, including Europe, Poland, Serbia, Uruguay, Turkey, Russia, USA, Mexico, Brazil, Singapore, India, Egypt, Thailand, Middle east and South Africa.

We based on "technological development, pollution remediation, wholeheartedly for customer services". We hope to cooperate with all customers from all over the world and build a better world together.

After Sales Service

Provide equipment certification and installation operating instructions.

Provide one-year spare parts.

Provide technical advisory services.

Provide guidance staff for installation and commissioning.

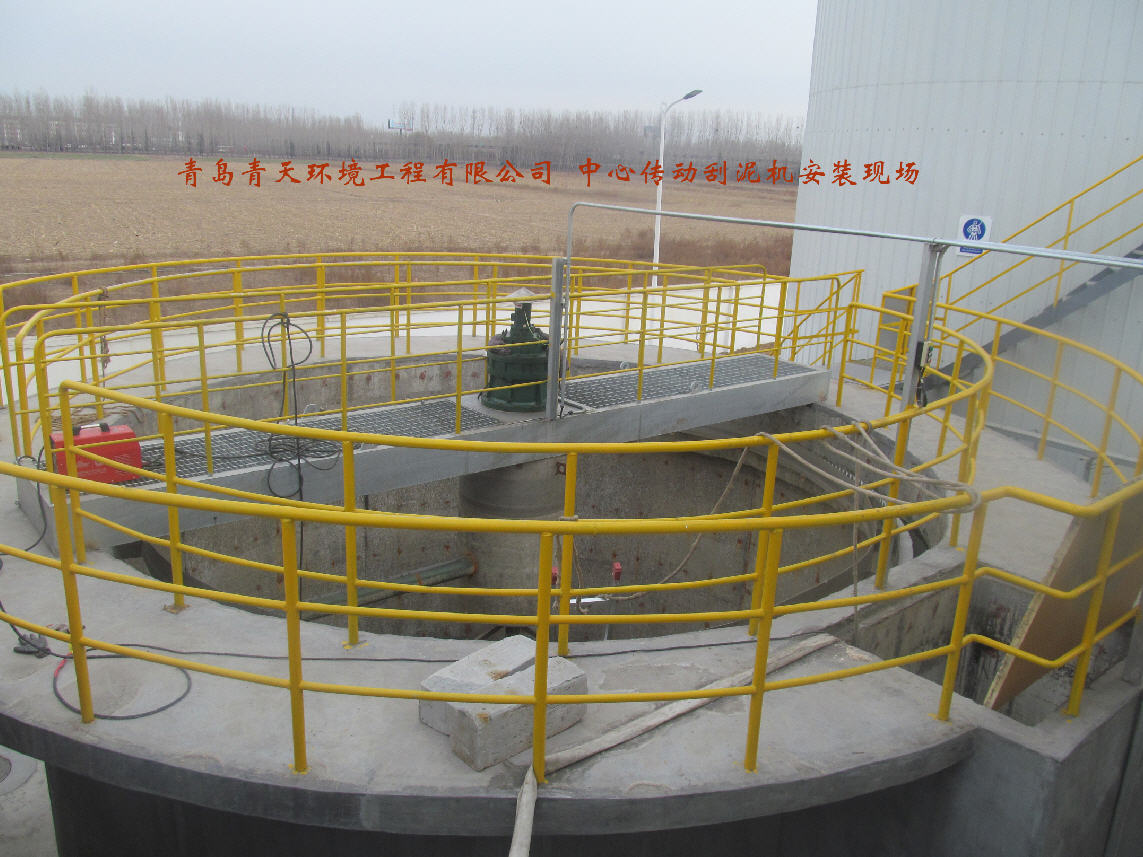

Photos