Air Flotation Equipment Special Vortex Concave Aeration Machine Caf

Product DescriptionCavitation air floatation Machine(CAF) for wastewater treatmentsSummarizeCavitation Air Flotation is an excellent sewage treatment technique, rational design, operation convenient a···

Introduction

Product Description

Cavitation air floatation Machine(CAF) for wastewater treatments

Summarize

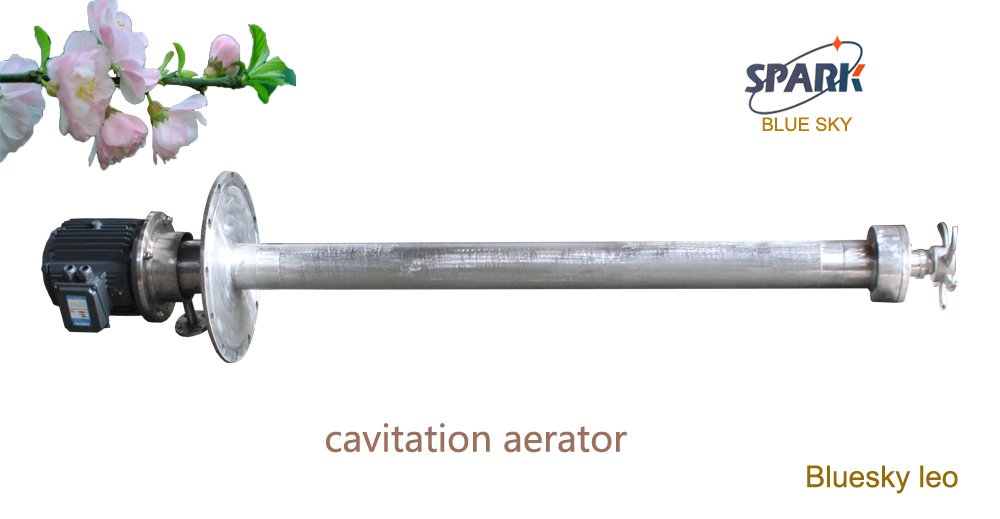

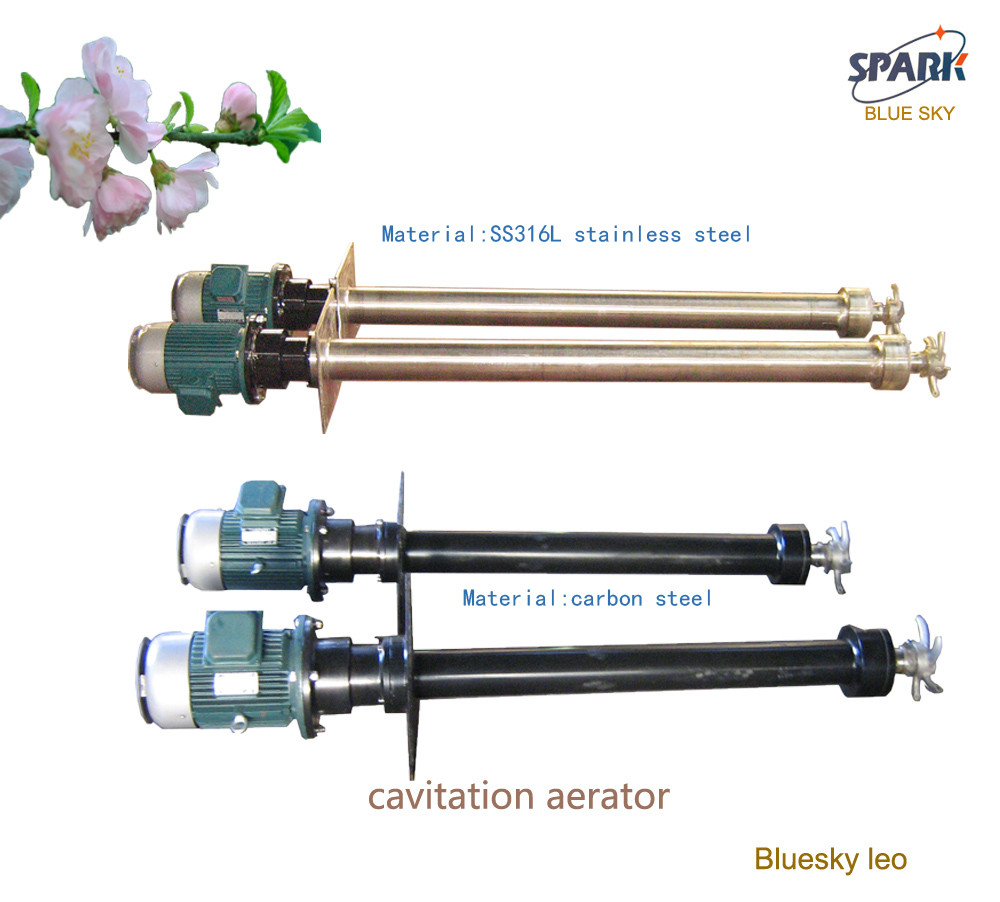

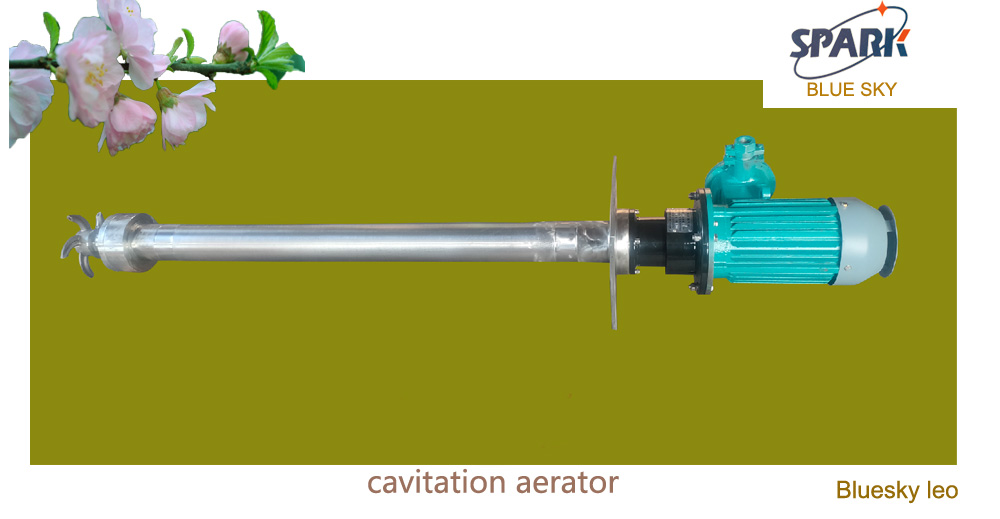

Cavitation Air Flotation is an excellent sewage treatment technique, rational design, operation convenient and economic, which can remove the suspended solid from the waste water by microscopic bubble. Cavitation aerator is the main part of the system.It can produces "microscopic bubble" directly.

Aerator is widely used by high-rate aeration of flotation and flotation tank in petroleum, petrifaction, textile, food, paper making, dyes and pigments, brewing, pharmacy, leather making and slaughtering industries wastewater treatment and municipal sewage treatment.

It is composed of motor, motor base, coupler, intake shaft, aerator cylinder, grease seal, mechanical seal and impeller outlet. Aerator cylinder can be made of carbon steel and stainless steel. Cavitation aerator bubble is formed through motor high speed revolution, negative pressure will occur when mixing the water flow. Then inhaling air through air intake; The air is inhaled into the water when pass through central shaft, rotates in the water after passing impeller, then formed fine air bubbles with diameter from 5um---15um. A stream of micro-fine air bubbles attach to solid suspension in the water rising to the surface of the water, then formed scums, fine air bubbles will last 50~60 seconds in the water.

Cavitation Aerator Features

Large aeration volume

High speed rising of fine bubbles , high density

Easy operation and management, lower power consumption

Little noise, long life span

No need air compressor, dissolved air vessel.

Single or multi aerator are all available based on customers application.Single aerator has the feature of

the system is capable of removing sewage grease, gum and fiber suspension, reduced BOD, COD, SS and other sewage load, and can improve the water quality.

2, Cavitation Aerator Specs

Parameter Table of THAF Cavitation Aerator | ||||

Specification | Short Cavitation Aerator | Long Cavitation Aerator | Remarks | |

single aerator capacity | ≤20T/H | ≥25T/H,≤75T/H | ||

Motor | Model | YX2-90L-4 | YX2-100L1-4 | the motor can be choosed Anti exposure type or IP55 motor. |

Power | 1.5KW | 2.2KW | ||

Speed | 1400r/m | 1420r/m | ||

Requirements pool depth(mm) | ≥1230 | ≥1830 | ||

Optimum pool depth(mm) | 1230 | 1830 | ||

Equipment length(mm) | 1650 | 2340 | Length including moto | |

Underwater part length(mm) | 1170 | 1780 | The length under the mounting plate | |

Cylinder | The pipe diameter is 114mm, made of Q275 steel(plastic anti-corrosion)or stainless steel. | |||

Intake shaft | The pipe diameter is 50mm, made of Q275 steel(plastic anti-corrosion)or stainless steel. | |||

Impeller | Five teeth, 304 or 316 stainless steel | |||

Mechanical seal | SUS304 or 316, the static ring is made of high strength wear resistant alloy | |||

Bearing | Japan NSK bearing | |||

Oil seal | Germany UKS oil seal | |||

Note: one long aerator is used for 25T/H or under 75T/H,two aerators are used for 100-175T/H,and three aerators are used for 200-320T/H,and so on. One short aerator is used for 20T/H or under 20T/H.Or according to the pool depth to choose: The pool depth 1.8 meters below the selection of short aeration machine, pool depth 1.8 meters above the selection of long aeration machine | ||||

3,Notes

1) The cavitation aerator must be run in the forward direction (clockwise, according to the direction of the red arrow).The cavitation aerator is prohibited to run if there is no water in the pool.

2) 2)You should always pay attention to the noise in operation, if there is noise, should immediately stop the machine, and check the motor , the aerator couplings and the glue zygotes whether they are damaged, if they are damaged must be replaced in time.

3) if there is any noise after the replacement of the adhesive, it should be checked whether the bearing or mechanical seal is damaged or flooded, and immediately shut down for maintenance or contact with the manufacturer.

4) if no aeration, first check the aeration machine whether it is reverse, the motor can be turned into a positive. Then check the impeller outlet whether is blocked, if congestion, need to clean up aeration impeller.

Send your message to this supplier

Photos